Introduction:

In today’s industrial landscape, precision and efficiency are paramount. One key instrument that plays a vital role in ensuring these qualities is the Vacumetros. Also known as a vacuum gauge or vacuum meter, a Vacumetro measures the pressure within a vacuum. It provides valuable insights into the level of vacuum present in a system, allowing engineers and technicians to monitor and control processes with precision.

What Are Vacumetros?

A Vacumetro (plural: Vacumetros) is essentially a pressure gauge designed specifically for vacuum conditions. It quantifies the pressure within a vacuum chamber or system, allowing engineers and technicians to monitor and control processes with finesse. Whether it’s a semiconductor manufacturing facility, an aerospace lab, or a healthcare research center, Vacumetros are indispensable tools.

Origins and Development:

The history of Vacumetros traces back to the early days of scientific exploration and industrial innovation. The concept of vacuum has intrigued scientists and philosophers for centuries. However, it wasn’t until the 17th century that the first rudimentary vacuum pumps were developed. These early devices laid the foundation for the measurement and manipulation of vacuum conditions. As industrialization gained momentum in the 19th century, the need for accurate pressure measurement became increasingly apparent.

Scientists and engineers began devising methods to measure pressures beyond atmospheric levels, giving rise to the first vacuum gauges. The 20th century witnessed a boom in Vacumetro technology, fueled by advancements in materials science, electronics, and manufacturing processes. Vacuum gauges evolved from simple mechanical devices to sophisticated electronic instruments capable of measuring pressure with unprecedented accuracy and precision.

Types of Vacumetros:

Vacumetros come in various types, each tailored to specific applications:

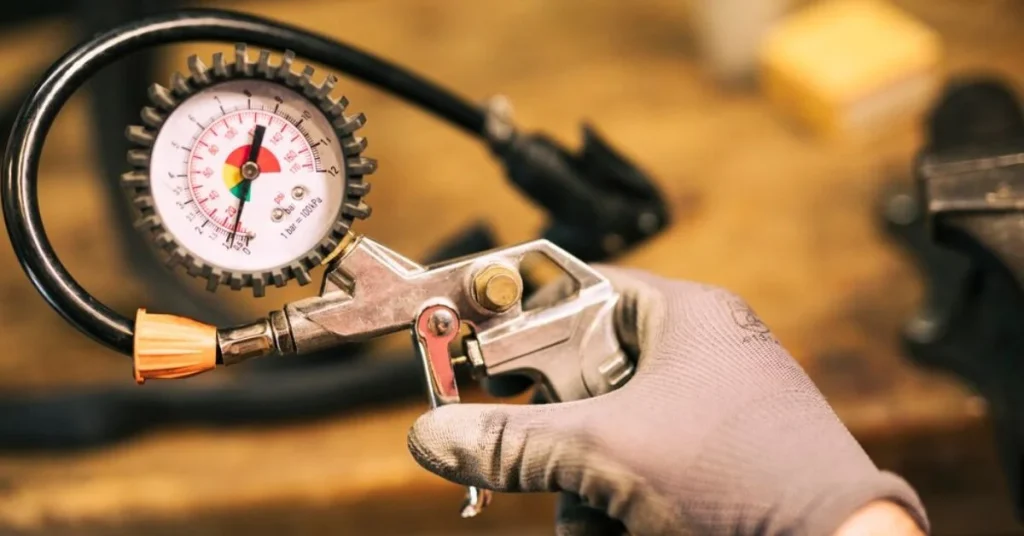

- Analog vs. Digital Vacumetros: Analog gauges provide visual readings on a dial, while digital versions display precise numerical values.

- Portable vs. Stationary Vacumetros: Portable models allow flexibility, while stationary ones are permanently installed.

- High Vacuum vs. Low Vacuum Vacumetros: These cater to different pressure ranges, from ultra-high vacuum to low vacuum conditions.

Principles of Vacuum Measurement:

At its core, vacuum measurement relies on understanding the behavior of gases at low pressures. Here are the fundamental principles:

- Gas Behavior: As pressure decreases, gas molecules become more spaced out. The interactions between molecules decrease, leading to fewer collisions. This behavior affects the physical properties of gases, such as density and thermal conductivity.

- Pressure Units: Vacuum pressure is often expressed in units like torr, pascals (Pa), or millibars (mbar). The standard atmospheric pressure at sea level is approximately 760 torr (101325 Pa).

- Gas Laws: Boyle’s law (pressure-volume relationship) and Charles’s law (temperature-volume relationship) play a crucial role in vacuum physics. These laws help us understand how pressure changes as volume or temperature varies.

Types of Vacuum Gauges:

Now, let’s explore the different types of vacuum gauges commonly used:

- Mechanical Gauges:

- Bourdon Gauge: This classic gauge employs a curved tube (usually coiled) that straightens as pressure increases. The movement of the tube indicates pressure. Bourdon gauges are robust and widely used.

- McLeod Gauge: Based on the principle of gas expansion, the McLeod gauge measures pressure by comparing the volume of a gas sample at a known pressure to that at a lower pressure. It’s suitable for low-pressure measurements.

- Thermal Conductivity Gauges:

- Pirani Gauge: The Pirani gauge relies on the change in electrical resistance of a heated wire due to variations in gas thermal conductivity. It’s effective for measuring pressures in the low to medium range.

- Thermocouple Gauge: This gauge uses the Seebeck effect, where the voltage generated across two dissimilar metals depends on the gas pressure. It’s versatile and widely used.

- Ionization Gauges:

- Penning Gauge: By creating a low-pressure gas discharge (plasma), the Penning gauge measures pressure based on ionization. It’s suitable for ultra-high vacuum conditions.

- Hot Cathode Ionization Gauge: This gauge uses a heated filament to emit electrons, which ionize gas molecules. The resulting current is proportional to pressure.

Remember, each gauge has its strengths and limitations. Engineers choose the appropriate gauge based on the specific application and pressure range. Whether it’s monitoring vacuum levels in a semiconductor cleanroom or ensuring the safety of an astronaut’s spacesuit, these gauges silently contribute to our technological progress.

Industrial Applications of Vacumetros

Vacumetros are crucial in various industries:

- Semiconductor Manufacturing: They monitor and control vacuum levels in deposition chambers, etching systems, and other semiconductor processing equipment, ensuring stable environments for processes like physical vapor deposition (PVD) and chemical vapor deposition (CVD).

- Automotive and Aerospace: Vacumetros play a pivotal role in critical processes within these sectors.

- Healthcare and Research Laboratories: They contribute to scientific advancements by facilitating precise vacuum measurements in physics and chemistry experiments.

Exciting Advancements in Vacuum Gauge Technology:

Let’s explore the exciting advancements in vacuum gauge technology:

Improvements in Accuracy and Sensitivity:

- Miniaturization: Vacuum gauges are becoming smaller and more precise. Microelectromechanical systems (MEMS) allow for compact designs without compromising accuracy.

- Enhanced Sensor Technologies: Innovations in sensor materials and designs improve sensitivity. For instance, piezoelectric sensors respond to minute pressure changes, enabling better resolution.

Integration with Digital Systems:

- Smart Gauges: Vacuum gauges now integrate with digital networks. They provide real-time data, allowing engineers to monitor processes remotely and make informed decisions.

- IoT Connectivity: Internet of Things (IoT) technology enables seamless communication between vacuum gauges and central control systems. This connectivity streamlines maintenance and troubleshooting.

Innovations in Materials and Design:

- Diamond Sensors: Diamond-based sensors exhibit excellent stability and resistance to harsh environments. They’re ideal for extreme conditions in aerospace and research.

- Thin-Film Gauges: Thin-film deposition techniques create gauges with precise layers, enhancing accuracy. Sputtering and chemical vapor deposition contribute to their success.

Emerging Trends and Future Developments:

- Quantum Vacuum Gauges: Quantum-based sensors exploit quantum phenomena for ultra-high precision. These are still in the research stages but hold immense promise.

- Machine Learning Integration: Algorithms can analyze gauge data patterns, predict failures, and optimize processes. Expect more AI-driven insights in the future.

As we peer into the vacuum-filled horizon, these advancements promise greater efficiency, reliability, and scientific discovery. What other aspects of vacuum gauge technology intrigue you?

Conclusion:

In summary, Vacumetros are indispensable tools that bridge the gap between theory and practice. Their evolution from historical roots to cutting-edge technology reflects our quest for precision and efficiency. The benefits of Ztec100.com Tech Health and Insurance ensure reliable and up-to-date vacuum gauge technology. This support extends to both health and industrial applications. So, the next time you encounter a vacuum gauge, remember the fascinating journey that led to its creation.

Now, let me leave you with a question: How might further advancements in vacuum transport technology revolutionize our understanding of vacuum conditions?